Description

Comes in 25kg Drum (Liquid Chemical)

POLYTAN 4F is a blended liquid treatment based on organic tannin, polymer sludge conditioners and alkali. It can be used either by itself or in conjunction with other supplemental FEEDWATER treatments to give a balanced treatment programme. POLYTAN 4F does not add substantially to the boiler water TDS, and hence is an ideal treatment for boilers which are susceptible to foam formation.

POLYTAN 4F controls corrosion by the dual mechanism of oxygen scavenging and the formation of a corrosion resistant tannate film. It prevents scale formation by converting residual hardness salts to a mobile non-adherent sludge that can be removed by blowdown.

POLYTAN 4F is also suitable for boilers with copper components which makes it perfect for use in typical land, maritime and heritage steam boilers.

Suitable for

Steam boilers

High, Medium and Low temperature hot water closed loop systems

Why use Polytan?

Polytan 4F is a high strength tannin based boiler treatment offering superior protection with an undiluted solution offering 4 times the tannin content than some competitor products marketed at heritage steam, this offers the user much greater value for money with a product that lasts much much longer.

Polytan 4F boiler corrosion inhibitor

- Traditional Tannin based Corrosion Inhibitor

- Very cost effective

- Excellent protection

- Protects steel, cast iron, copper, brass

It should not be used in systems which contain aluminium or galvanised steel.

Dosage rate

1 litre / 1000 litres of system water and make-up

Example Boiler control limits

pH 10+

Tannin: 12 – 20

TDS: 3500mg/l max.

How to use it

Polytan 4F should be added to the system at an initial dosage rate of 1 litre/ 1000 litres of system water content whenever the system is drained or loses a significant quantity of water then the additional Polytan 4F should be added at the rate of 1 litre / 1000 litres of water added.

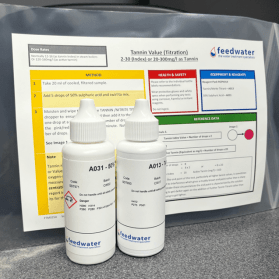

The active inhibitor reserve can be measured using a simple Tannin testkit.