What is Activ-Ox?

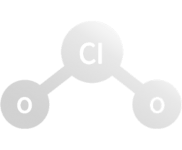

Activ-Ox® is Feedwater’s patented Chlorine Dioxide generation process. It is simpler, safer and more effective than other ways of producing chlorine dioxide the chemistry is very simple and requires the activation of two precursor chemicals. Activ-Ox was developed by Feedwater to treat potable (drinking) and industrial water systems to disinfect and prevent the growth of unwanted or dangerous bacteria such as Legionella.

Because of the simplicity and uniqueness of the chemistry Feedwater developed, the Activ-Ox concept could be adapted to many more applications than conventional ClO2 systems. Feedwater developed a simplified dosing system to dose the chemical which required no storage of gas instead just requiring a small reaction tee piece as the chemical reaction is instant and high yielding, meaning it can flow directly into the water stream being treated.