Cooling System Chemicals

Feedwater is a manufacturer and supplier of a range of high-quality cooling tower treatment chemicals for UK and export.

If not treated correctly, a cooling system can rapidly become choked with scale and corrosion products and become a breeding ground for all manner of problematic microbes. The cooling tower itself can become fouled with microbial slime, algal growths and if incorrectly treated can be the cause of Legionnaires’ disease.

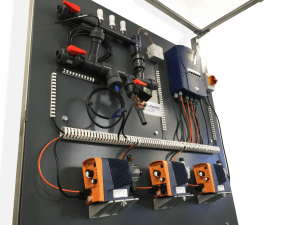

Problems are invariably inter-related and a comprehensive treatment programme is required which will involve corrosion inhibitors, scale inhibitors, polymer dispersant and micro biocides.

Our range of Cooling Water Chemicals are available to see by clicking the link, additionally, a selection of our popular chemicals are also available to order online.

Export and Toll Blend

Feedwater also has agreements with distributors around the world and is actively seeking new partners to bring Feedwater products into new markets, if you feel this is you please contact us. As well as this Feedwater provides toll blend services to service providers who require the partnership of a manufacturer to supply speciality chemicals with their name on.