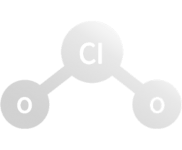

Chlorine Dioxide Generators – ClO2 Dosing Systems

Feedwater’s range of Activ-Ox Chlorine Dioxide Generators or more accurately ‘dosing systems’ are the simplest, safest and most cost-effective way to produce a controlled dosage of ClO2 for a wide range of commercial, industrial and water treatment applications.

A conventional chlorine dioxide generator tends to be an expensive and complicated system for dosing ClO2, which requires 2 or 3 hazardous chemicals and is very much for the specialist user. Activ-Ox dosing systems by contrast use low hazard pre-cursors, are easy and safe to use and are a low-cost way to generate ClO2 for almost all applications where a conventional chlorine dioxide generator would have historically been used.

Important Warning!

Many chlorine dioxide suppliers don’t actually make the generator themselves – they are simply distributors. Feedwater is actually the manufacturer of the Activ-OX® dosing systems and also makes the chemicals – so if you want the best product at the best price then contact us today!