Marketing Manager for Feedwater Ltd

In charge of website design and content up keep.

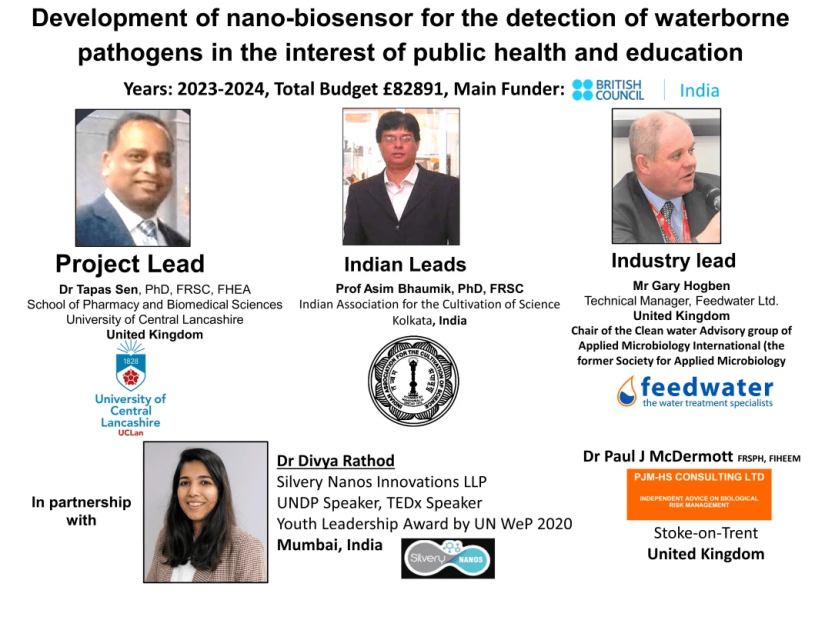

Project to Develop Nano-Biosensors for the Detection of Waterborne Pathogens in the Interest of Public Health and Education We are very pleased to announce Feedwater is participating in an international project with the University of Central Lancashire and the Indian Association for the Cultivation of Science. The project will end in an international conference in…

Winners of the Sustainable Business of the Year Award – Feedwater We are very proud to announce that Feedwater has been recognized as the Sustainable Business of the Year at the Wirral Business Awards 2023. This is a testament to the hard work, commitment, and innovative strategies implemented by our dedicated team. We endeavour not…

Spas & Hot tubs are a popular way for people to relax and unwind, but did you know that they can also be a breeding ground for harmful bacteria?

One such bacterium is Pseudomonas aeruginosa, which can cause a range of infections including folliculitis rashes as well as otitis media and otitis interna middle and inner ear infections.

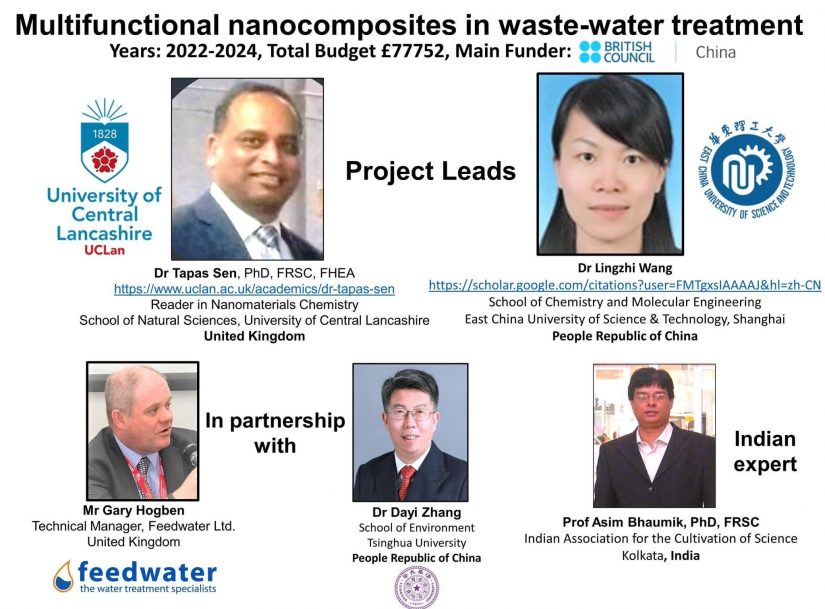

Position at UCAN project for multifunctional nanocomposites in waste-water treatment An exciting opportunity to join a major international research team headed in the UK by Dr Tapas Sen and in China by Dr Lingzhi Wang of East China University in Shanghai. The position is based at the University of Central Lancashire. This project is supported…

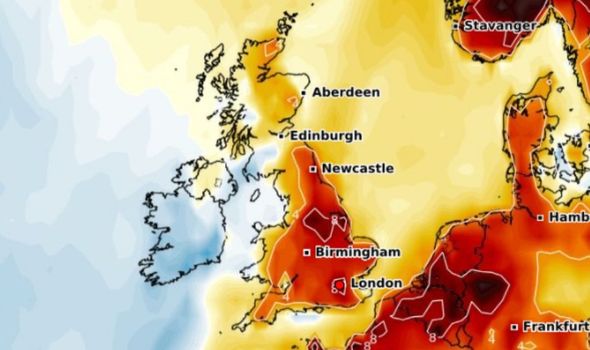

With the increase in extreme weather events due to Global Warming & Climate Change, the UK is in for hotter summer heatwaves. Temperatures in the 30s and even lower 40s are going to become more of the norm which presents an issue for businesses where office domestic systems are monitored to control Legionella.

Dr McCoy highlights the reasons water recycling and reuse is key to improving water efficiency in many industrial sectors. And although there have been several government and private initiatives to assist in the implementation of recycling projects, the uptake of these projects has been somehow limited. Yolla’s featured research paper summarises findings from an extensive study that was done between 2010 – 2017 and revisited in 2021 following the significant increases in material and energy costs in the UK.

Feedwater Ltd is pleased to share details of a research collaboration brought together by The Innovation Agency; the Academic Health Science Network for the North West Coast in November 2021.

The project is intended to form the basis of a BSI standard for air disinfecting equipment. The partners; Liverpool University, Innovation Agency NW, Feedwater Ltd, and Essential Microbiology Ltd all providing essential elements in this project.

The following is a summary from the submission made to the Research Collaboration of the Year award detailing the project and the success which has led the implementation of new criteria for suppliers by NHS supply chain.

Feedwater Ltd is delighted to announce it has joined companies such as Unilever, TSB and Aviva in signing up to the Good Business Charter (GBC), an accreditation that seeks to raise the bar on business practices for employees, tax, the environment, customers and suppliers.

Bromgard Video We have recently finished the creation of a new video which explains the Bromgard chemistry for complete cooling tower treatment. Bromgard is a 2 part chemistry the first part of which combines a scale & corrosion inhibitor, dispersant and Bromide – a Bromine pre-cursor. Once dosed into the system the second part of…

This article covers the differences in chlorine and bromine and how pH is a major driver in choosing Bromine as your primary biocide in cooling systems.