Feedwater Ltd is pleased to share details of a research collaboration brought together by The Innovation Agency; the Academic Health Science Network for the North West Coast in November 2021.

Feedwater Ltd is pleased to share details of a research collaboration brought together by The Innovation Agency; the Academic Health Science Network for the North West Coast in November 2021.

The project is intended to form the basis of a BSI standard for air disinfecting equipment. The partners; Liverpool University, The Innovation Agency, Feedwater Ltd, and Essential Microbiology Ltd all providing essential elements in this project.

The following is a summary from the submission made to the Research Collaboration of the Year award detailing the project and the success which has led the implementation of new criteria for suppliers by NHS supply chain.

Summary

Through the pandemic, there has been a high incidence of nosocomial COVID infection. This has caused staff and patients, entering hospital without covid, to become infected in hospital. Furthermore, there has been reduced elective capacity because of social distancing/deep cleaning between procedures reducing availability of facilities. We were commissioned by the Chief Scientific Officers office to develop an understanding of the efficacy of UVC Airscrubbing HVAC equipment. This equipment is on the market but no standards exist to provide assurance that the machines were effective at killing airborne pathogens. It is thus difficult to make effective data-based procurement decisions should regulators or trusts specify air disinfection equipment as a mitigation strategy.

The collaborating parties were brought together by The Innovation Agency in November 2021. This project has developed a protocol to determine the efficacy of ultra-violet air decontamination units. The investment has created a facility to test machines at LUFT and a bio-validation and bio-Evaluation process has been developed between the partners. This will form the basis of a BSI standard for air disinfecting equipment. The partners (Liverpool University, Innovation Agency, Feedwater Ltd and Essential Microbiology Ltd) provided differing elements of this extensive collaboration.

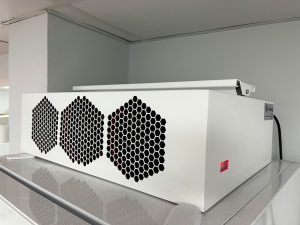

The Facility

The test facility is a bio-secure unit permitting the dissemination (through a nebuliser) of bacteria (Micrococcus luteus) into the approximately 60m3 air space. Dosed air was re-circulated using electric fans.

Air samples were taken to provide a background count. After this phase, the UV devices were activated drawing air through the UV unit. Samples were taken at designated time intervals. The samples are passed through a Coriolis air sampler, suspending the bacteria in liquid. All samples are then transported to the Feedwater laboratory for analysis.

The project has established a consistent process for determining reduced microbial counts achieved by the units. The method developed can be adapted for other types of devices, (e.g. ozone or plasma based)

This project could not have gone ahead without the key participants – each was dependent upon the other for success and there were no prior links before this collaboration. The project offers a defined validation methodology, comparative efficacy data for manufacturers/end-users, together with reduction of infectious particles to mitigate against respiratory spread.

NHS Supply Chain will now insist that to be eligible for NHS procurement, companies making/distributing air disinfection equipment will be subject to testing at the Liverpool Lab at LUFT. This is a significant regional success.

About Feedwater

Feedwater Ltd is a UK Water Treatment Company, established in 1976 specifically to supply products and services for the treatment of water for steam boilers, cooling towers, building services and industrial processes. We were helping prevent Legionnaires’ Disease before most people had even heard of it.

Our teams of consultants and service engineers cover the whole of the United Kingdom and Republic of Ireland (Eire). We have also been exporting water treatment products and services to clients abroad for over 30 years providing them with quality British water treatment solutions they trust.

Feedwater Ltd operates an onsite microbiological laboratory UKAS accredited for the analysis of numerous waterborne bacteria including Legionella, E.Coli and Pseudomonas. Using these facilities and expertise has enabled Feedwater to collaborate on a number of research projects with Universities and development agencies to come up with innovative solutions.