Mechanisms

Carryover also known as priming is any solid, liquid or vaporous contaminant that leaves a boiler with the steam. In low/medium pressure boilers (<100 bar) entrained boiler water is the most common cause of steam contamination.

Carryover also known as priming is any solid, liquid or vaporous contaminant that leaves a boiler with the steam. In low/medium pressure boilers (<100 bar) entrained boiler water is the most common cause of steam contamination.

Both mechanical factors such as boiler design, high water levels, load characteristics and chemical factors such as high solids concentration, excessive alkalinity, presence of contaminants contribute to the creation of carryover.

Two of the most common mechanical causes of carryover are operation in excess of design load and sudden increases in load.

Foaming is one of the mechanisms of chemical carryover. Foaming tendencies are increased with increases in alkalinity and solids content. Stable foam bubbles contain boiler solids and are carried forward with the steam giving rise to carryover.

Oil and other organic contaminants can react with boiler water alkalinity to give crude surface active materials which cause foaming and carryover.

Effects

Boiler water solids carried over with steam will form deposits in non-return and other control valves. Process streams can be contaminated by carryover affecting product quality.

Deposition in superheaters can lead to failure due to overheating and corrosion.

Steam turbines are potentially prone to damage by carryover as deposits on turbine blades creates imbalance reducing efficiency and capacity. Solid particles in steam can lead to erosion and corrosion in both turbines and other equipment.

Prevention of Carryover

The prime means of preventing carryover is to have good mechanical steam separation devices. For low/medium pressure fire tube boilers where steam purity is not stringent, gravity separation is normally satisfactory. (At least 14 bar and saturation conditions the density of water is 115 times greater than that of steam). As steam pressure rises the difference in density reduces (at 69 bar water is only 20 times more dense than steam) making gravity separation less effective. Steam separators are then used to improve purity and are usually installed in the steam drum of water tube boilers.

Primary separators utilise the difference in density as the means of separation bypassing steam through a series of baffles which reduces turbulence or centrifugal (cyclone) separators.

Secondary separators, where steam is directed in a frequently reversing pattern through a large contact surface. A mist of boiler water collects on the surface and is drained from the unit.

Control of boiler water chemistry is essential to minimise carryover and allow mechanical separation to work effectively. The parameters that must be controlled are:

- Total dissolved solids

- Alkalinity

- Silica

- Organic contamination.

These should be maintained within the boiler manufacturer guidelines or those of BS 2486.

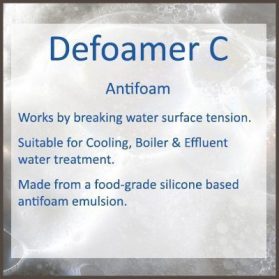

Whenever carryover is being caused by excessive boiler water concentrations an increase in boiler blowdown rate is normally the simplest and most expedient solution. If carryover is still occurring and increasing blowdown is uneconomic then the addition of antifoam agents can economically reduce carryover. Use of an antifoam may allow the boiler to operate at higher water concentrations, Feedwater offer a product called Defoamer C which is suitable for this job, for more information visit the product page for product usage guidance.

If you would like to book a free site visit consultation with one of our experts to discuss your boiler water treatment, the protection of your industrial equipment, processes and reducing running costs please contact us.