Boiler Water Oxygen Scavengers

A chemical oxygen scavenger is used to remove the residual oxygen from the boiler feed water in order to protect not only the boiler but also control corrosion in the hotwell (or feed tank) and the condensate return lines.

Sulphite/Sulfite

Our product range includes chemical oxygen scavengers based on sodium sulphite or sulfite which is fast acting, easy to test for and ideal for low-pressure boiler applications.

Corroban 25 – FDA-approved partially neutralised sodium sulfite (uncatalysed and also suitable for chlorine removal in drinking water and RO make-up) – POA

Corroban 26 – FDA-approved partially neutralised sodium suphite oxygen scavenger (catalysed) – Order Online

Corroban 27 – FDA-approved highly concentrated sulphite for maximum cost-effectiveness. – POA

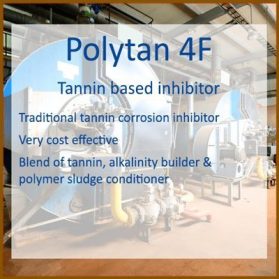

We also supply a range of tannin oxygen scavengers as an alternative to sulphite or sulfite chemicals for low-pressure steam applications.

Tannin

Tannin chemicals have a number of benefits:

- Tannin’s don’t add to the boiler TDS so reduce the need for blowdown and save energy

- they have a dual corrosion protection mechanism since they not only remove the oxygen but also form a corrosion resistant tannate film on the boiler steel

- they are brown in colour so are easy to detect and test for

- they are particularly suitable for low or variable feed water temperatures and very good at protecting idle and intermittently used boilers.

Whilst often seen as a traditional boiler water treatment chemical, Feedwater tannin products use high-quality freeze-dried tannin extracts, chosen specifically for their oxygen scavenging performance and which are blended with state of the art polymer sludge conditioners and alkalinity builders.

Feedwater’ tannin products are suitable for most low-pressure boiler applications and particularly popular with operators of steam engines, locomotives, traction engines and heritage steam boilers.

Boilertan 4 – A liquid tannin oxygen scavenger which is a direct replacement for DM 4 in 1. – POA

Polytan 4F – A mildly alkaline multifunctional tannin chemical incorporating two polymer sludge conditioners. – Order Online

Polytan 4C – A strongly alkaline multifunctional tannin chemical incorporating two polymer sludge conditioners. – Order Online

Polytan 8F – A highly concentrated liquid tannin treatment incorporating a polymer sludge conditioner (FDA approved). – POA

Feedwater Ltd is a UK based Industrial water softener manufacturer, supplier and water treatment specialist with over 30 years experience in designing and installing commercial water softeners and industrial water softening systems.

Feedwater Ltd is a UK based Industrial water softener manufacturer, supplier and water treatment specialist with over 30 years experience in designing and installing commercial water softeners and industrial water softening systems.