Why Stabilised Chlorine Dioxide is a poor substitute for Activ-Ox®

Stabilised Chlorine Dioxide is a marketing term coined in the 1990s to sell a new generation of chemical products which deliver chlorine dioxide in small quantities and low concentrations.

But there is little or no chlorine dioxide in Stabilised Chlorine Dioxide solutions. They normally consist of a buffered sodium chlorite solution, which must be activated with a dangerously strong acid to slowly liberate small quantities of chlorine dioxide gas. The activated mixture must be stored for a number of hours while the gas is generated, then the finished mixture is delivered to the point of use. This can be inconvenient, dangerous, messy and inefficient, read below or watch the video to learn about how Activ-Ox is entirely different.

Activ-Ox is a much safer, easier and controllable way of treating water systems efficiently with chlorine dioxide:

- instantaneous high yield production of chlorine dioxide – saves time and chemicals

- uses a weak acid activating solution – much safer than corrosive strong acid

- no storage of concentrated chlorine dioxide solutions – no storage vessel or reaction time needed

- injection in direct proportion to water flow – much more efficient as it’s only produced on demand

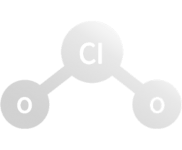

How does Activ-Ox produce Chlorine Dioxide?

The Activ-Ox process uses 2 pre-cursor chemicals in much the same way a conventional chlorine dioxide generator does, but with some very important differences. The patented Activ-Ox chemistry releases ClO2 instantaneously, whereas a conventional chlorine dioxide generator or Stabilised Chlorine Dioxide dosing system can take several hours to give its maximum yield of ClO2.

The chlorine dioxide yield of the Activ-Ox process is very high, converting around 95% of the precursor chemical to ClO2. This is higher than other processes and much higher than some so-called Stabilised Chlorine Dioxide systems, which not only give a low yield but take a long time to do it.

Another critical difference between Activ-Ox and other chlorine dioxide systems is that it doesn’t need a strong acid to work. Activ-8, the matching pre-cursor to Activ-Ox is a special blend of food/drinking-water-approved weak acids, which is classified as non-hazardous. The patented Activ-Ox chemistry is so different from the way conventional chlorine dioxide generators work – you could even activate it with Coca Cola!

How is Activ-Ox dosed?

Because, unlike other processes for producing chlorine dioxide, Activ-Ox releases ClO2 instantaneously and completely, we have been able to develop a much simpler dosing system than a conventional chlorine dioxide generator or Stabilised Chlorine Dioxide system. No gas is released, and there is no need for a reaction vessel storing dangerously concentrated mixtures, instead, the ClO2 is produced directly in solution in a special “T” fitting which is installed in the water stream to be treated.

There’s more to see, click the links to jump to the details you most need to know!

How is the Chlorine Dioxide level controlled?

The Activ-Ox dosage is typically controlled by a signal from a water meter in the make-up line to the system being treated. This provides precise, direct fail-safe proportional control over the dosage of Chlorine Dioxide and is inherently much simpler and safer than most chlorine dioxide generators. The Activ-Ox dosing system can be programmed to deliver the required chlorine dioxide level and will add ClO2 at that rate based on the water flow.

Since water supplies and water distribution systems have a chlorine dioxide demand, particularly if they have an established biofilm, each Activ-Ox dosing system is supplied with a simple test kit to enable the residual Chlorine Dioxide to be tested at strategic locations and the dosage level to be adjusted to establish and maintain the required free chlorine dioxide residual throughout the system being treated.

Whilst water meter controlled dosage is the most common arrangement we can also supply systems with direct chlorine dioxide monitoring and timer controlled dosage.