Fire Tube or Shell Boilers

Fire Tube or Shell Boilers

This is the most common type of boiler used in small and medium sized industrial installations. Fire tube boilers are often produced as ‘packaged’ units complete with pumps and control system, requiring only connection to a suitable water and fuel supply before commencing operation.

In fire tube boilers the flame and heat gases from combustion are confined within tubes arranged in a bundle within a water drum. Water circulates on the outside of the tubes. As the water changes to steam it rises to the top of the boiler drum and exists through a steam header.

Fire tube boilers are efficient steam generators for low to medium pressure steam requirements usually below 15 bar, although shell boilers operating up to 30 bar are known and steaming rates up to 70,000 kg/hr. Operating at higher pressures and steaming rates requires thicker plates and tube walls making the design less economic.

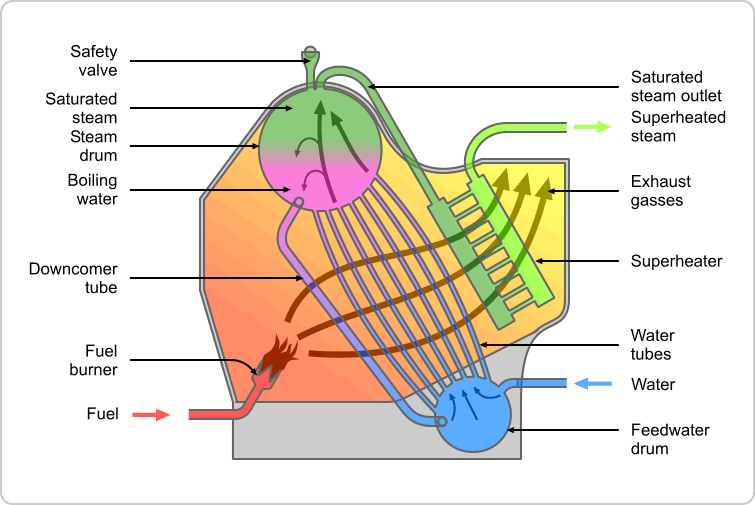

The water tube boiler differs from the fire tube in that the flame and hot combustion gases flow across the outside of the tubes and water is circulated within the tubes. Fuel combustion occurs in a furnace and some of the water tubes usually form the furnace walls.

Early boilers were of this type although in the most common type – Lancashire boilers – there were no smoke tubes to recover energy from the exhaust gases, hence the poor efficiency of these early designs. In a simple water tube circuit, steam bubbles form on the heated side of the tubes. The resulting steam-water mixture has a density less than that of cooler water on the unheated side and rises, creating a circulation through the system. The steam bubbles rise until they reach the steam drum where steam is released from water into the vapour space.

Water tube boilers may have natural circulation, where circulation of water between a steam drum at the top and a mud drum at the bottom occurs due to density differences. In forced circulation boilers a pump provides the water circulation, Figure 7. This gives a more positive control of the circulation pattern than that created simply by density differences. This is important if the boiler operates over a wide capacity range.

Water tube boilers are commonly used in electrical utilities and large manufacturing sites where requirements are for large capacity and/or high pressure steam. Most water tube boilers are built on site, although smaller ‘packaged’ units are becoming available.

Other Boiler Types

Whilst fire tube and water tube boilers are the most common types, especially where high steam capacity is required, other designs do exist.

i) Coil Boiler

The basic design is for feedwater to be pumped to single or multiple coils arranged around a burner. The heat input and fluid flow produce steam at the coil exit of between 10-20% wetness. This steam can then be passed through a separator and superheater if required. The coil arrangement can include an economiser section in the exit flue gas. The feedwater can be treated raw water or a mixture of this and returned condensate. Separator drain water can be returned to the feedwater tank or dumped, or the feedwater can be added to the separator drain for recycling through the coils. These types of boilers can carry very high (up to 8000ppm) dissolved solids in the water phase at the coil exit without detriment to steam purity. The flow through the coils must ensure that the inside of coils in the furnace area are properly wetted and cooled to ensure freedom from dry out, corrosion and deposition.

The potential for corrosion in this type of boiler is increased because there is no opportunity for dissolved oxygen and carbon dioxide to escape. To prevent corrosion and deposition good water treatment is essential.

ii) Electrode Boilers

Electrode and electrically heated boilers provide convenient small packaged units where relatively small volumes of steam are required quickly.

Two general types are found.

– Immersion electric boilers operate in a similar manner to fire tube boilers but heat is provided from electricity not the combustion of fuels. Water treatment is similar to that for fire tube boilers.

– Electronic resistance boilers utilise the internal resistance drop through the boiler water to generate heat, therefore the conductivity of the feedwater is critical. These boilers are prone to corrosion and scale build-up so only good quality feedwater treatment should be used.